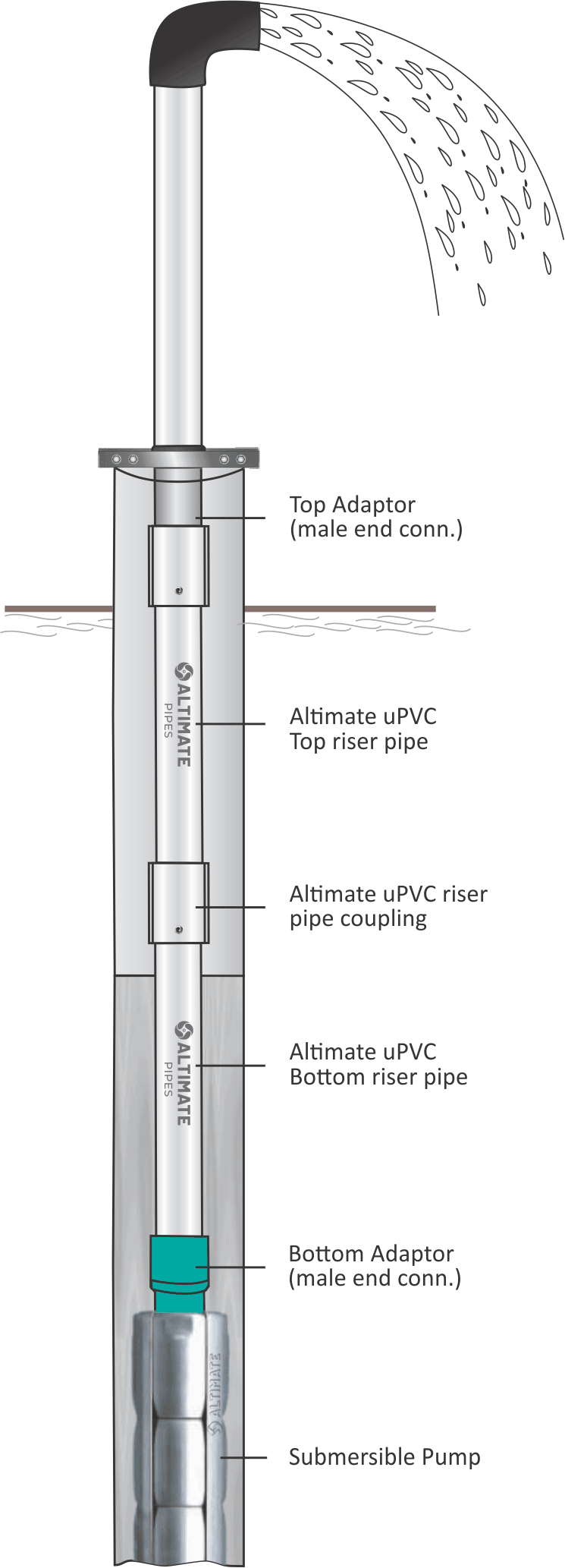

Altimate Borewell uPVC Riser pipes which are also known as borehole pipe, Column pipe or drop pipe for Submersible pump. Altimate Borewell uPVC Riser pipes are suitable for water extraction from the bore wells. These pipes are uniquely designed and manufactured using lead free compound on highly advanced, state-of-the-art CNC machines. Altimate Borewell uPVC pipes have been designed to withstand system load comprising the weight of the pump, water and pipes with an adequate factor of safety.

Our Riser pipes are exported to countries across Africa , Europe , Asia and North America.

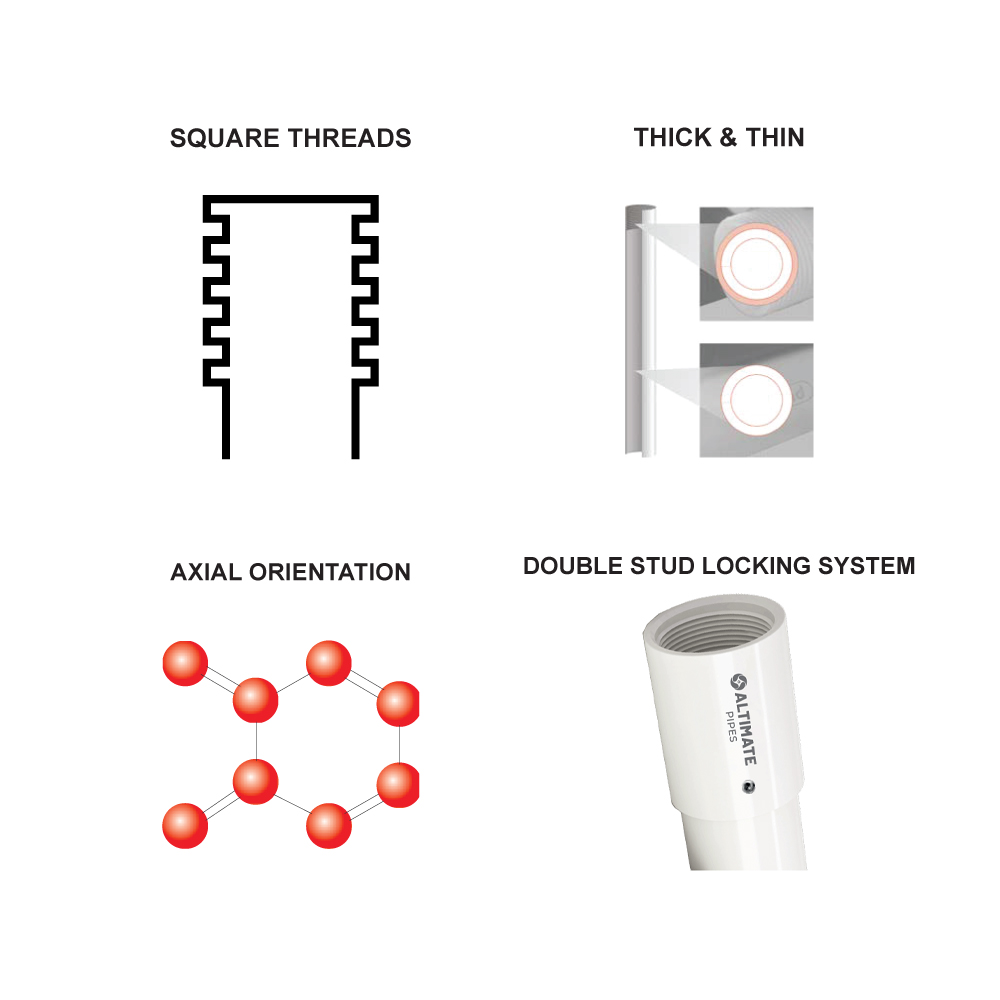

Altimate Riser pipes comes with a DOUBLE SCREW LOCKING SYSTEM which ensures tremendous tensile strength, high temperature resistance and reliability.

Altimate Borewell Riser pipes offer many advantages, thereby emerging as the best alternative to conventional metal pipes.

Borewell Riser pipes are light weight, have a high tensile load capacity, leak proof joints, have a long life, and are economical. Its square threaded coupling joint ensures ease of joining as well as an optimum load holding capacity. A high torque resistant Stud – locking system and specially designed rubber “O” ring ensure trouble-free operations.

Our stringent quality assurance approach across all stages of manufacturing gives the product a high degree of reliability, making Altimate Borewell Riser pipes a preferred choice for farmers, users in domestic and commercial establishments, and quality-conscious people across the globe.

Altimate Borewell Riser in Coupler variants in standard lengths of 3 meters. These pipes are available in sizes between 25 and 150 mm (1” to 6”) diameter with a full range of pressure ratings in Eco, Eco+ , Medium, Standard, Heavy, Super Heavy , Extra Super Heavy type as per requirements based on installation depth from 50 to 450 meters.